Blister packs are widely used packaging solutions that offer exceptional product safety, convenience, and ease of use. This article explores the benefits, applications, and considerations associated with blister packs.

1. Definition and Structure of Blister Packs:

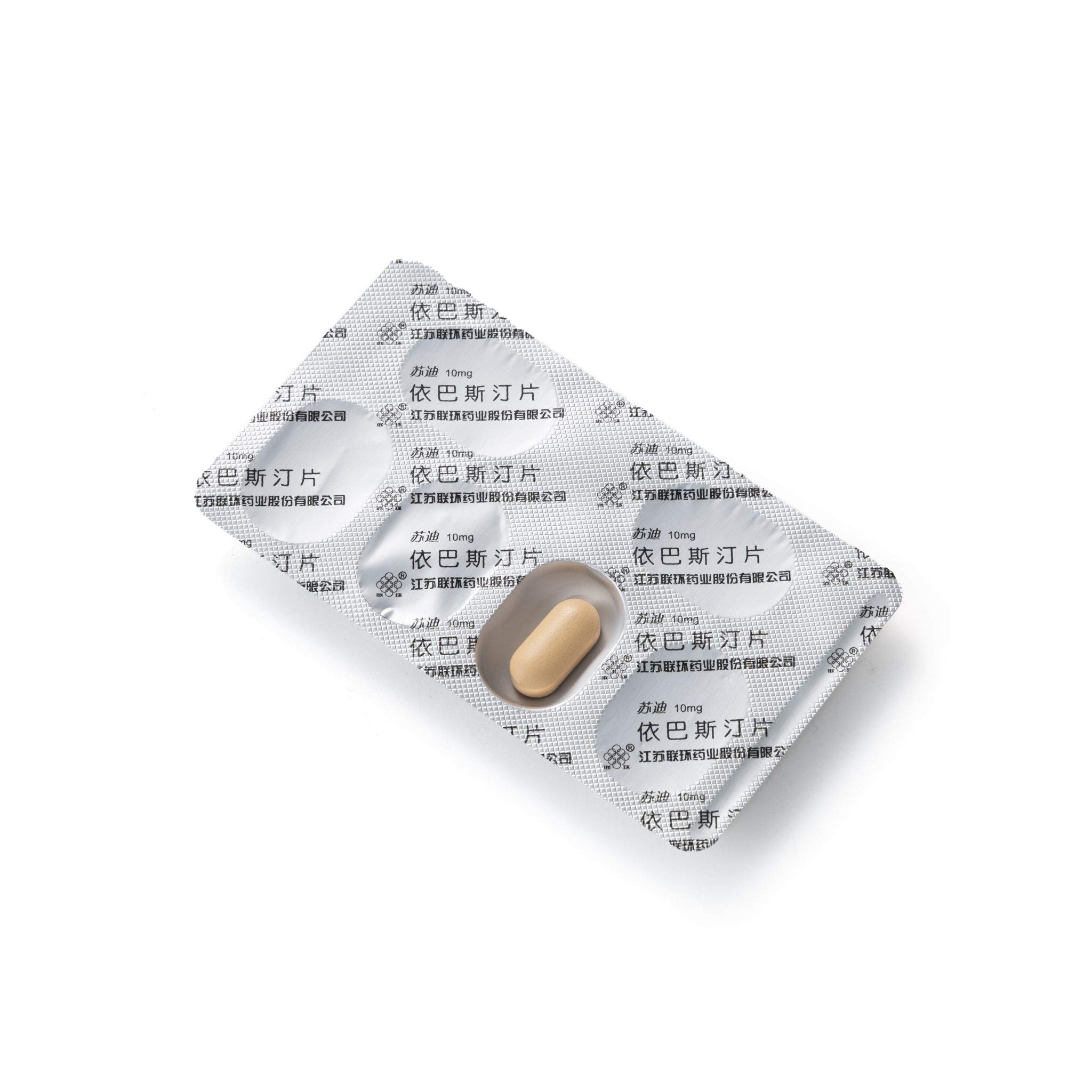

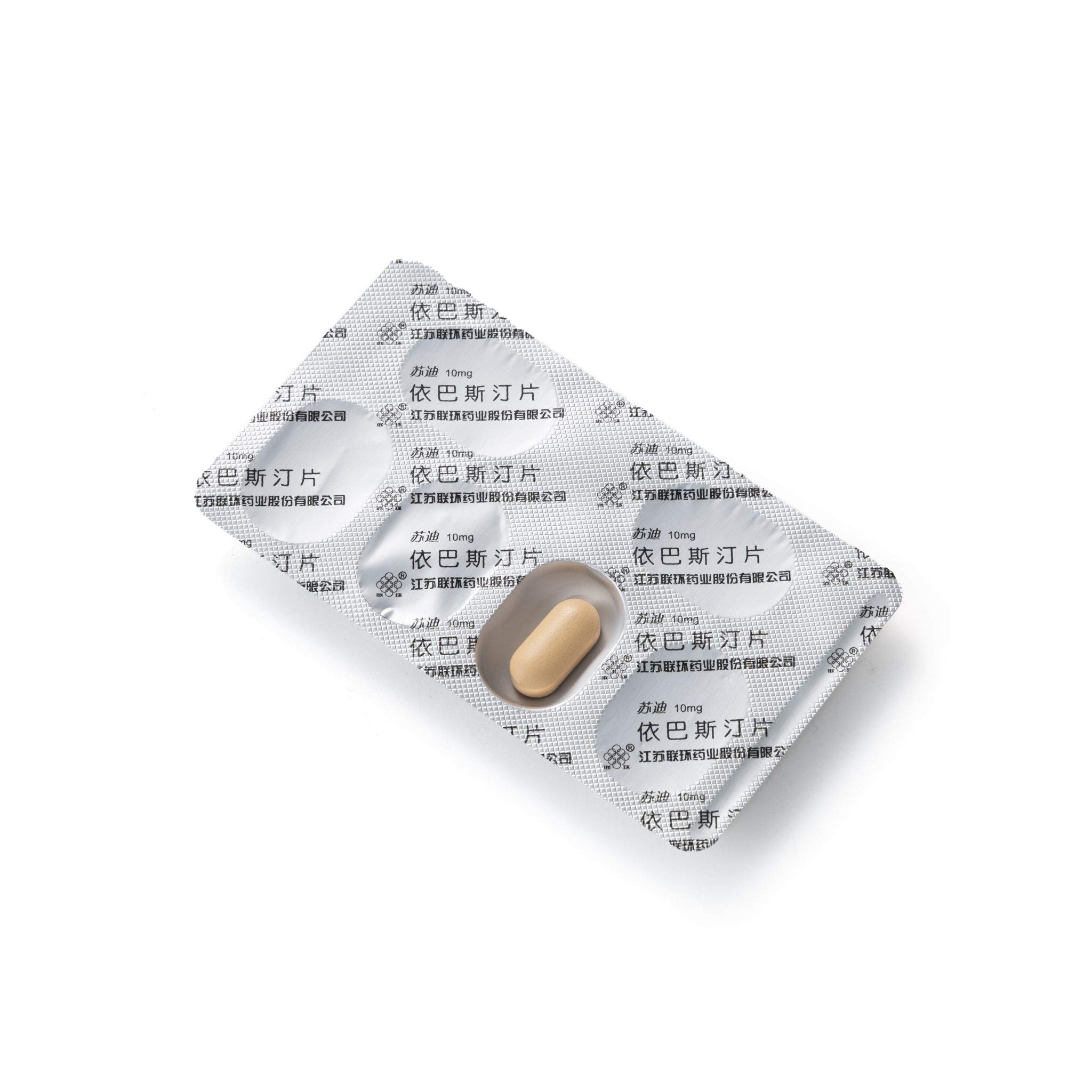

● Blister packs are a type of packaging consisting of a plastic cavity (blister) that securely holds individual items or doses.

● The blister is usually sealed with a lidding material, such as aluminum foil or plastic film.

● This structure protects against tampering, contamination, and moisture.

2. Advantages of Blister Packs:

● Product Protection: Blister packs shield products from damage, including physical impact and exposure to air, moisture, and light.

● Contamination Prevention: Blister packs provide a protective barrier, reducing the risk of contamination during handling, storage, and transportation.

● Extended Shelf Life: The sealing properties of blister packs help preserve product quality and efficacy over a longer period.

● Dose Accuracy: Blister packs enable accurate dosing, particularly in pharmaceuticals, ensuring proper medication administration.

● Convenience: The individual compartments in blister packs offer easy and organized access to each unit, promoting user-friendliness.

● Portability: Blister packs are lightweight, compact, and easily transportable, making them ideal for travel or on-the-go use.

3. Applications of Blister Packs:

● Pharmaceuticals: Blister packs are extensively used in the pharmaceutical industry to package tablets, capsules, and other dosage forms. They ensure product integrity, facilitate accurate dosing, and improve patient compliance.

● Medical Devices: Blister packs are utilized to package medical devices such as syringes, bandages, and diagnostic tools. They protect the contents from contamination and enhance sterility.

● Consumer Goods: Blister packs are employed for packaging various consumer goods like electronics, batteries, cosmetics, and food supplements. They enhance product visibility and provide a tamper-evident feature.

4. Considerations for Blister Pack Design:

● Child-Resistant Features: Blister packs can incorporate child-resistant closures or designs to prevent accidental ingestion by children.

● Compatibility: The choice of blister pack materials should be compatible with the product to maintain stability and prevent interaction.

● Environmental Impact: Sustainable blister pack options, such as recyclable materials and reduced packaging waste, should be considered.

● Accessibility: Design considerations include ease of opening for users with limited dexterity and visual impairments.

● Cost Efficiency: Balancing packaging requirements with cost considerations is crucial to ensure affordability in the production process.

Blister packs have been widely adopted as a preferred packaging solution for the pharmaceutical industry and for several other consumer goods. The advantages of blister packs, such as product protection, extended shelf life, dose accuracy, portability, and convenience, have made them ideal for use in various applications.

In addition to their traditional uses, blister packs have also found applicability in specialized fields like clinical research, where they are used to pack medical devices and biological samples. Blister packs can protect these delicate and sensitive items from contamination and temperature variations, which is essential for maintaining their integrity during transportation and storage.

One recent development in blister pack technology has been the integration of RFID tags. An RFID (Radio Frequency Identification) tag is a small electronic device that uses radio waves to communicate information about the packaged item. Integration of RFID tags in blister packs enables easy tracking of products throughout the supply chain, from manufacturing to delivery to point-of-sale.

Blister packs’ design considerations are crucial to improving the user experience and increasing patient compliance. One such consideration is the incorporation of interactive technology, such as QR codes or augmented reality, into the blister pack design. This technology enables patients to access critical information like drug instructions, dosage, and side effects instantly. Moreover, it enhances patient engagement and understanding of the medication’s benefits and limitations, which can lead to improved health outcomes.

As with any packaging material, there are environmental concerns associated with blister packs. However, blister pack manufacturers have started to offer eco-friendly options like biodegradable plastics and recyclable materials. Additionally, companies are exploring ways to reduce the amount of material required while still maintaining the necessary level of protection and ease of use.

In conclusion, blister packs are a versatile packaging solution that offers an array of benefits, including product protection, convenience, and user-friendliness. They have found widespread applications in various industries, and innovative design features like the integration of RFID tags and interactive technology have increased their usefulness. While environmental concerns exist, the industry is actively seeking ways to minimize its impact through sustainable blister pack options.

Blister packs have become an essential packaging solution, offering product protection, convenience, and extended shelf life. Their applications span pharmaceuticals, medical devices, and various consumer goods. By considering factors like product compatibility, environmental impact, and accessibility, manufacturers can optimize blister pack design. With their numerous advantages, blister packs continue to play a significant role in enhancing product safety and meeting consumer demands.

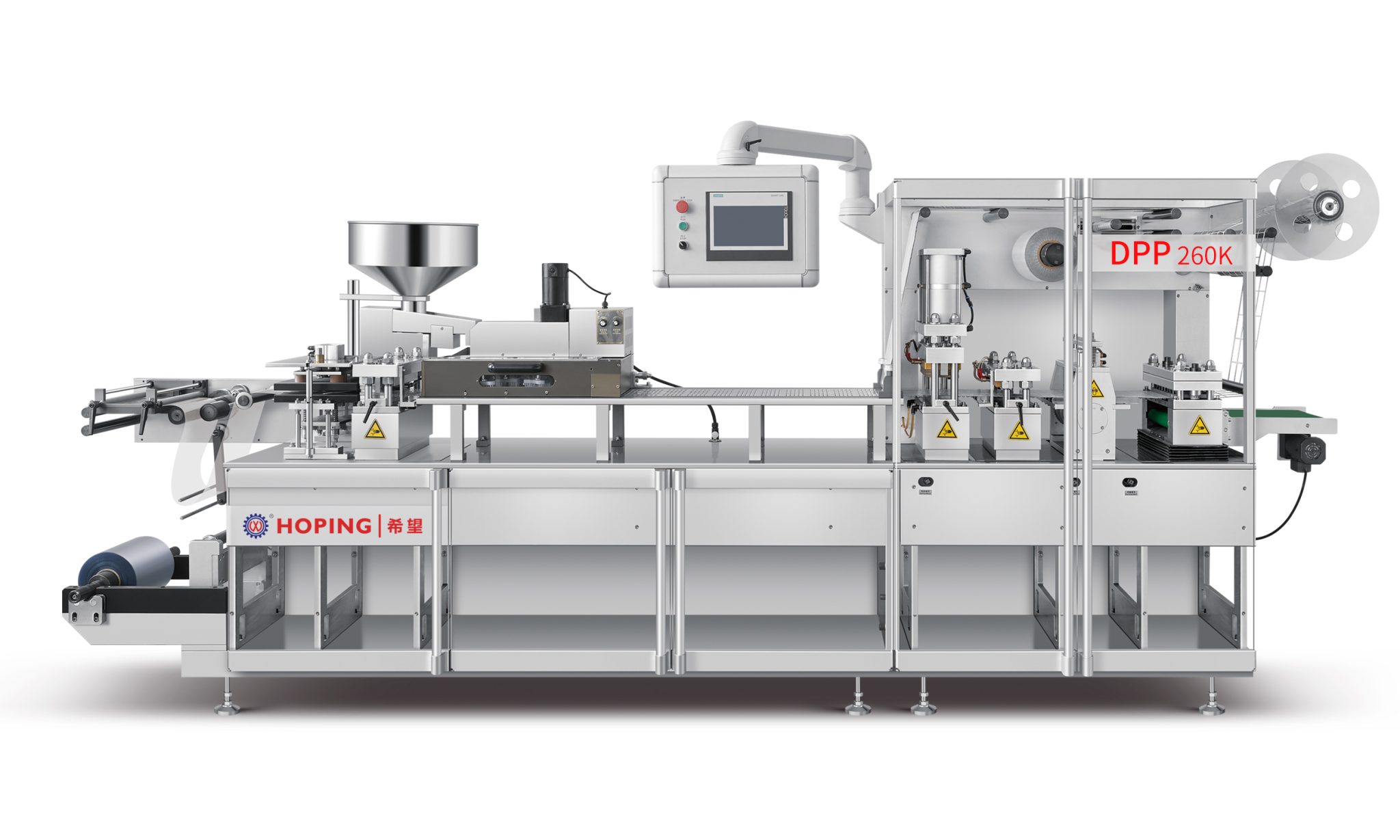

As a manufacturer of pharmaceutical packaging equipment, Hoping Machinery strives to gain a deep understanding of industry needs and provide solutions that meet market demands, enabling customers to achieve high efficiency and excellent quality. Whether it is small-scale production or large-scale production, our blister pack machines are flexible and adaptable, maintaining stable high-speed performance to ensure that customers always maintain a competitive advantage.

click on the image to view our product

You can visit our official website to browse more pharmaceutical packaging equipment. Hoping Machinery appreciates your support!

VR

VR