Full servo high speed machine line, defining the new trend of products in the next decade

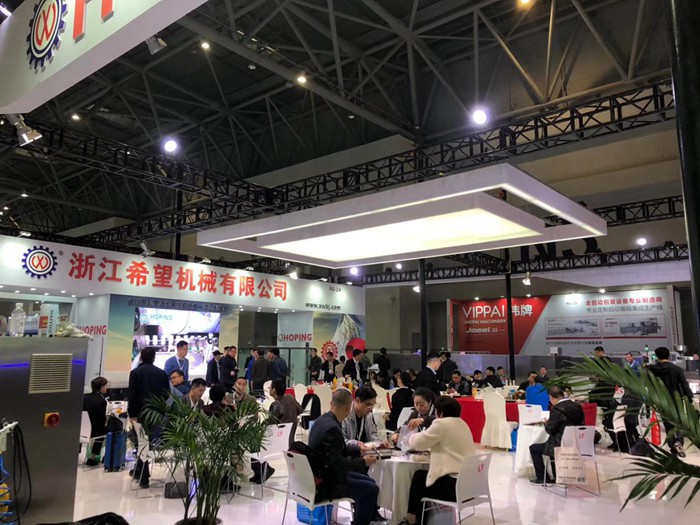

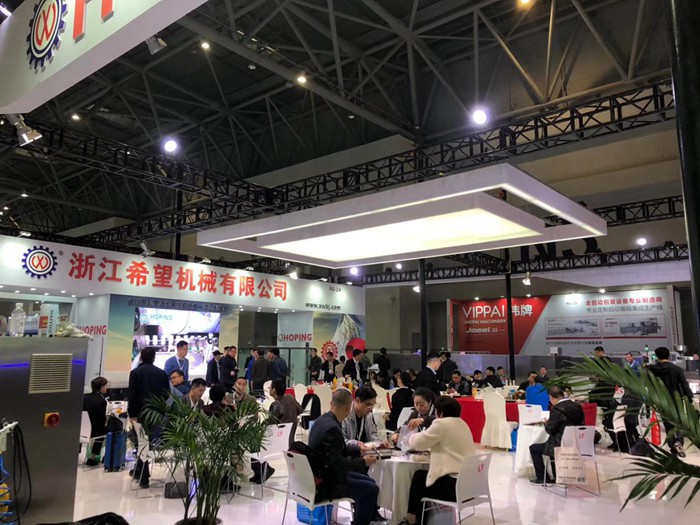

From Nov. 5-7th, the 58th (Autumn 2019) National Pharmaceutical Machinery and China International Pharmaceutical Machinery Expo was grandly held at the Chongqing International Expo Center. The exhibition area is over 180,000 square meters with 9,800 booths. The equipment on display covers nearly 10,000 sets of equipment in eight categories, including pharmaceutical machinery, API machinery, and pharmaceutical packaging machinery. There are also 1,320 exhibitors and tens of thousands of audiences gathered to share the event.

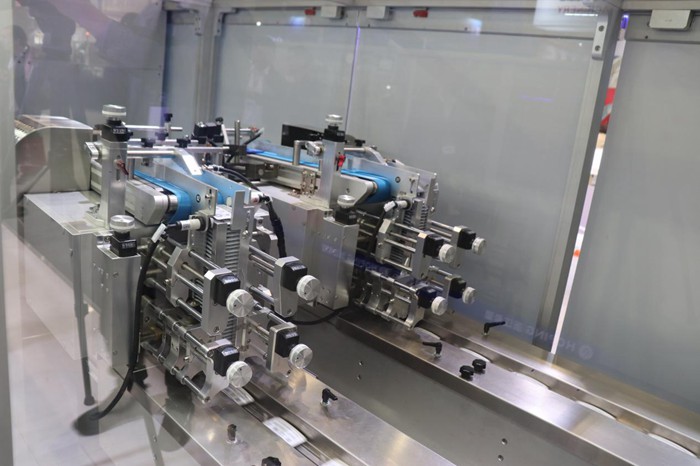

Zhejiang Hoping Machinery Co., Ltd. (hereinafter referred to as “Hoping Machinery”), the manufacturer of the machine line, brings DHL800 full servo high-speed blister-cartoner link machine, DHL700 full servo high-speed blister-cartoner link machine and DXWHL600 full servo high-speed blister-flow packing-cartoner link machine made their debut, attracting the attention of many domestic and foreign exhibitors. Then Mr. Li Wenlei, the technical director of Hoping Machinery, was interviewed on the spot on some issues of the company in expanding foreign markets in recent years.

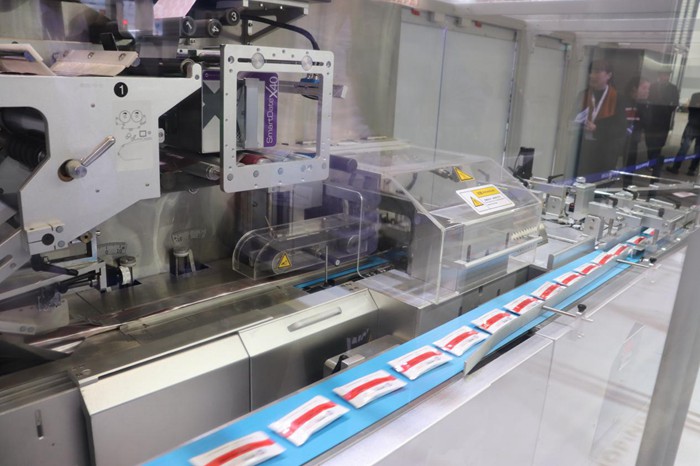

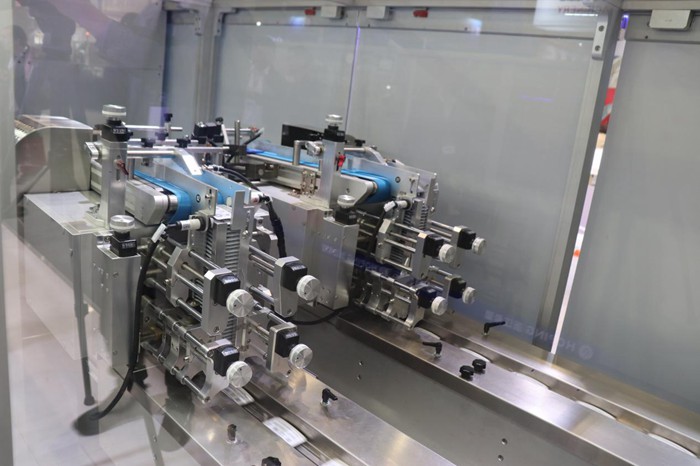

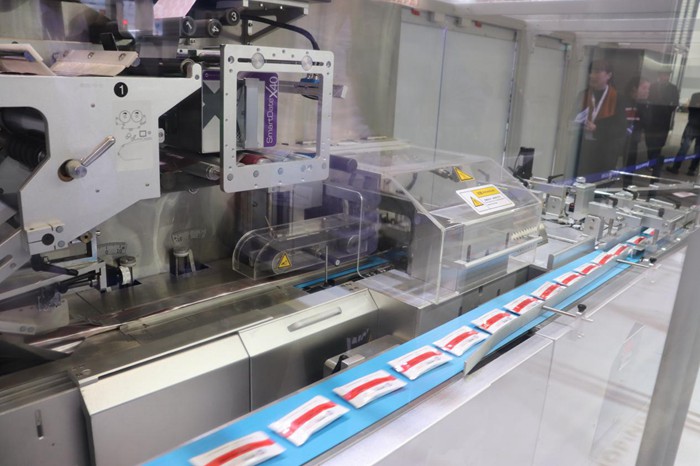

At this exhibition, Hoping Machinery exhibited three Lines. DXWHL600 full servo high-speed blister-flow packing-cartoner link machine is a product that will be highlighted in this exhibition. The dual-track production mode maximizes capacity matching of the blister machine(600 blister/min) and reciprocating flow packing machine(400 pack/min), and the production output can reach 300 pack/min after confluence, which greatly improves production efficiency. Mr. Li said that this machine line, which he mainly introduced, is one of the important equipment launched for the global market.

In addition to fully digital production, this equipment also incorporates information modules on the basis of automated production modules. Based on the digital control method developed by the Beckhoff motion controller, reliable data collection, convenient storage, standardized transmission, and the configuration of the multi-location quality monitoring, comprehensive quality control, convenient traceability, and fully digital production can be realized. “In the past, we did not know the specific production efficiency, the number of alarms and failures in a day, but through such a production line data management system, all data will be recorded and reports will be generated, allowing customers fully understand the production situation.” said Mr. Li.

Nowadays, in the packaging of medicine and food, companies are paying more and more attention to high efficiency, low energy consumption, and precise packaging, which also requires packaging machinery to continuously develop higher-quality, high-tech packaging equipment. Hope Machinery is a technology-based enterprise integrating R&D, production, sales, and related services. It was established in 2001 and has been developing for over 20 years. The company is located in the Ruian high-tech industrial park, with a total area of 28,000 square meters.

Over the years, with high-quality equipment and innovative technology, Hope Machinery’s products have cooperated with more than 1,500 domestic pharmaceutical, cosmetic, and food companies, and the products have also been exported to more than 60 countries and regions such as the United States, Germany, Japan, and Australia.

“We look forward to a better breakthrough in the next decade. Therefore, through the specialization, internationalization, large-scale and comprehensive exhibits of the pharmaceutical machine exhibition, we will redefine the products for the next ten years.” Mr. Li said, “Hope Machinery’s vision is to share and compete in the globalized international market with as much power as possible in the next ten years.”

Mr. Li said that in the future, Hoping machinery will still focus on the market demand for medicine machines and provide customers with more complete and thoughtful services. At the same time, it will seize the market trend, continuously develop and launch new products, and help the healthy development of packaging equipment and pharmaceutical equipment industries.

VR

VR