No. 88, Weiwu Road, High-tech Industrial Park, Ruian, Wenzhou, Zhejiang Province

Tel: 86-577-65579899

WhatsApp: +86 13356105292

E-Mail: info@hoping.email

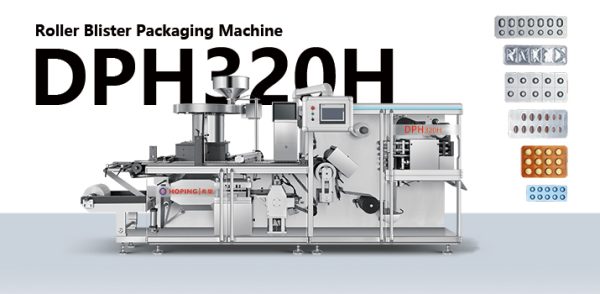

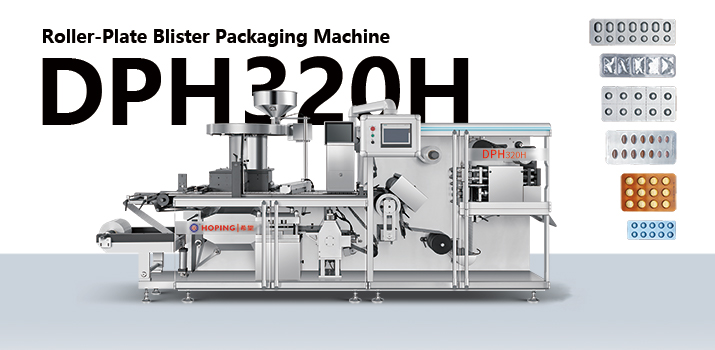

Blister Machine DPH320H

Blister Machine

Product Description

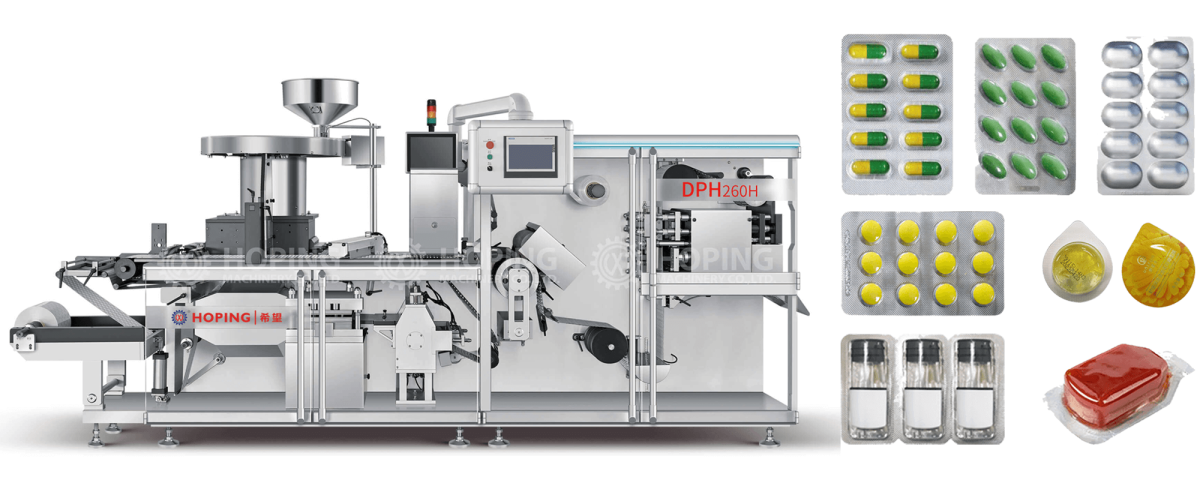

The blister machine operates on the principle of continuous drum sealing and is widely used in the packaging of various products. Blister machines meets the packaging needs of the pharmaceutical, food production, cosmetics manufacturing, medical device and other industries.

Product Features

- Maximum capacity 600 blisters/min[i]

- Continuous roll seal

- Different feeding methods depend on customer’s needs

- PLC control system and Siemens smart 1000 (10 inch) man-machine interface screen

- Dual servo drawing, stable and accurate operation

- Easy to change mold

- Splicing station for easy refueling

- Staggered blister strip-free scrap cutting (waste saving)

- Designed to meet GMP requirements

- [i] Produced according to the standard board size 80*57mm*mm

[i] Production according to the standard plate size 80*57mm*mm

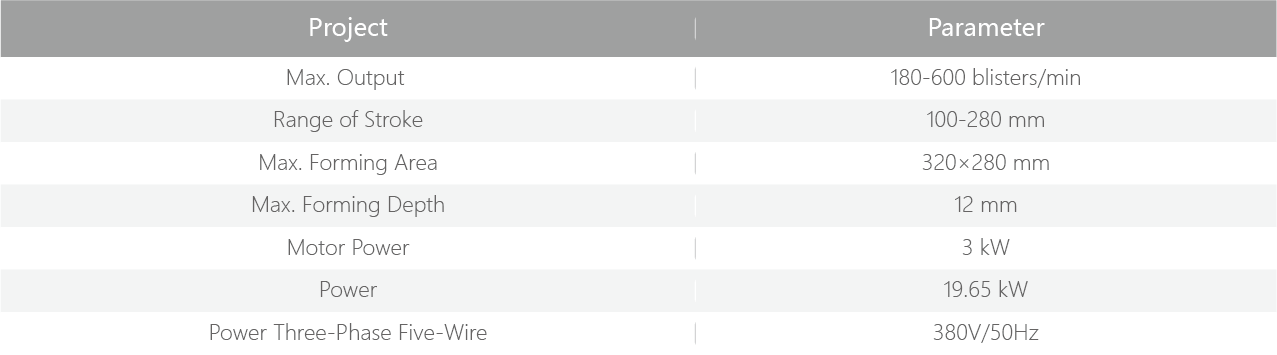

Technical Data

*The above parameters are for reference only, please contact sales for actual parameters.

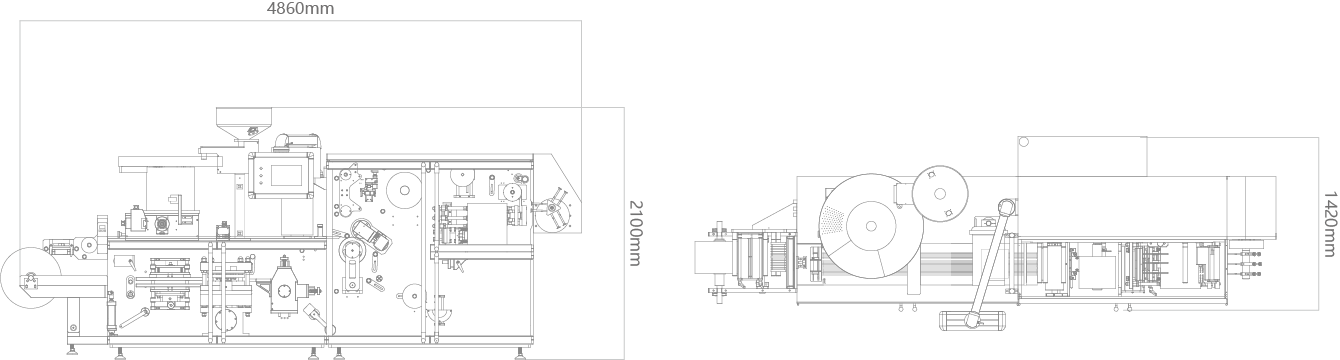

Dimension

Machine Detail

Reasons for choosing Hoping blister machines

22 years of machine manufacturing experience

22 years of machine manufacturing experience

Strong Technical Strength

We have strong technical innovation capabilities, and have more than 120 invention patents and utility model patents.

Good Sales Service

We have the ability to respond quickly in terms of services, and can solve customer needs in a timely manner. We have reached strategic cooperation with more than 100 companies.

About Hoping Machinery

Zhejiang Hope Machinery Co., Ltd. was established in 2001. It is a scientific and technological enterprise integrating research and development, production, sales and related services of packaging equipment for pharmaceuticals, food, cosmetics and electronic products. The main products are: flat-plate, roller-type aluminum-plastic, aluminum-aluminum blister packaging machines,automatic cartoning machines, pillow packaging machines, Intelligent digital packaging machine and production line. Hope Machinery has passed ISO9001 international quality management system certification, ISO14001 environmental management system certification, ISO45001 occupational health and safety management system certification, EU CE certification, and has reached cooperation with more than 2,000 pharmaceutical, cosmetics, and food companies. The company’s products are exported to more than 40 countries and regions such as the United States, Germany, Japan, Australia, Russia, Southeast Asia, Europe, Africa, South America, Taiwan, and Hong Kong.

Our Clients

About Blister Machine

What is blister machine?

A blister machine is a type of equipment used in the packaging industry to create blister packs. Blister packs are a widely used form of packaging that consists of a cavity or blister made of plastic or aluminum, which holds a product securely, and a backing or lidding material that seals the blister.

De blister machine come in different sizes and configurations, ranging from small manual machines for low-volume production to fully automated systems for high-speed production lines. These machines offer efficiency, precision, and consistency in creating blister packs, making them widely used in industries such as pharmaceuticals, healthcare, electronics, and consumer goods.

There are several benefits to using blistering machine in the pharmaceutical industry. One major advantage is that they provide a high level of protection for the medication, ensuring that it remains safe and effective for the patient. Blister packaging also allows for precise dosing, as each blister contains a single dose of medication, making it easy for patients to follow their prescribed treatment regimen.

In addition to their protective and precise dosing capabilities, blistering machine are also highly efficient and cost-effective. These machines can produce large volumes of blister packs in a short amount of time, reducing production costs and increasing profitability for pharmaceutical manufacturers.

There are a variety of different types of blistering machines available, each designed to meet specific needs and requirements. Some of the most common types of blistering machines include rotary blister machine, in-line blister packaging machines.

Overall, blistering machines are an essential piece of equipment in the pharmaceutical industry, providing a safe and effective way to package and distribute medication to patients.

Working process of blistering machines

The blisteing machine automates the process of forming the blisters, loading the products, sealing the blister packs, and separating them. Here is a breakdown of the typical steps involved in using a blister packaging machine:

1.Forming the blisters: The machine takes a roll or sheet of plastic or aluminum film and uses heat and pressure to form the desired blister shape. This can be done through thermoforming, where the film is heated and molded into the desired shape using a mold, or cold forming, where the film is pressed into the cavities using pressure without heating.

2.Loading the product: Once the blister cavities are formed, the machine automatically loads the products into each cavity. This can be done manually or with the help of automated feeding systems, depending on the specific machine.

3.Sealing the blister: After the products are loaded, a lidding material, often a foil or plastic film, is placed over the blister tray. The machine applies heat and pressure to seal the lidding material to the blister, creating a sealed package. Various sealing methods can be used, such as heat sealing, cold sealing, or ultrasonic sealing, depending on the machine and materials being used.

4.Cutting and separating:After the blister pack is sealed, a machine cuts and separates the individual packs from larger rolls or sheets. This can be done by rotary cutting (rotary wheel cutting the package) or using a stamping mechanism.

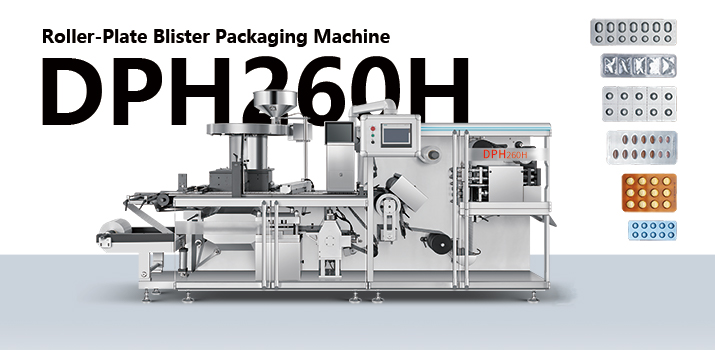

Related Products